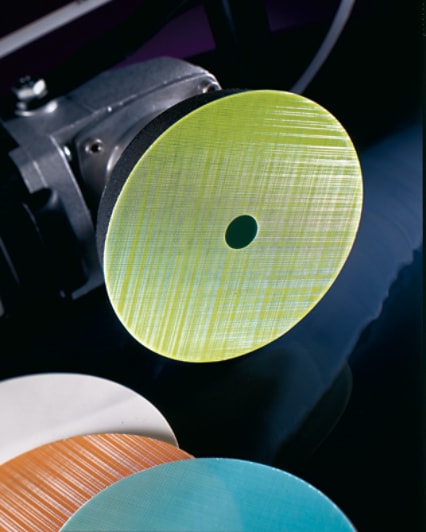

3M™ Trizact™ Hookit™ Film Disc 268XA

- | Select product options for IDs.

Details

Highlights

- Proprietary 3M™ Trizact™ abrasives start sharp and stay sharp, resulting in more predictable finishes and improved, consistent results

- Creates high gloss level for glass defect repair and solid surface finishing

- Micron sized abrasive pyramids produce a high-gloss finish

- Well suited for use on mini random orbital sanders to produce a polish-ready finish

- Produces finer finishes than paper and film-backed abrasives

We manufacture 3M™ Trizact™ Hookit™ Film Disc 268XA using proprietary micro-replication technology where micron-graded aluminum oxide particles are formed into tiny pyramids of abrasive mineral and then coated on a film backing. As these pyramids wear, fresh, sharp mineral is continually exposed to produce a consistent cut and a predictable, fine finish.

3M™ 268XA easily removes scuffs, scratches and acid marks on glass from TV screens to airplane windscreens and architectural glass

When compared to conventional abrasive products, our 3M™ Trizact™ abrasives produce a finer finish, achieve results faster, and last longer. The 3M™ Trizact™ Hookit™ Film Disc 268XA is suitable for use on a variety of solid surfaces, topcoats, and to accommodate most finish and process requirements. It is manufactured with the 3M™ Hookit™ attachment system for quick mounting and removal and to hold the disc securely in place during use. Hookit™ discs conveniently and firmly attach to a hook-and-loop backup disc pad (sold separately) on rotary or random orbital tools, can be removed cleanly and easily, and can be re-used again and again for the life of the disc. This disc can be run wet or dry.

Better Results in Less Time, Fewer Steps

Unlike conventional abrasives, our 3M™ Trizact™ discs start sharp and stay sharp, resulting in more predictable finishes and improved, consistent quality. We made 3M™ Trizact™ discs to last longer than conventional discs and provide precise finish control so that operators can reduce grade sequences, requiring fewer process steps and fewer abrasive products. Three-dimensional structures uniformly distributed over the entire surface ensure consistent performance and eliminate disc-to-disc variation.

Long-Lasting, Self-Sharpening Abrasive Mineral

The 3M™ Trizact™ Hookit™ Film Disc 268XA uses aluminum oxide abrasive mineral. Aluminum oxide is a popular choice among industrial professionals because of its cut-rate and long life. This mineral is a tough, durable abrasive that self-fractures to expose fresh cutting edges in use, whereas traditional abrasives, such as garnet, quickly wear down with use. Due to its high cut-rate, hardness, strength, and low heat retention, aluminum oxide mineral is widely used in grinding applications in addition to sanding and finishing use. Aluminum oxide is suitable on a wide variety of substrates in both woodworking and metalworking, including ferrous alloys.

| Matte Finish | |||

| Product | Grade | Damp/Dry | |

| Step 1 | 366L | 100μ | Dry |

| Step 2 | 268XA | A35 | Damp |

| 268XA | A10 | Damp | |

| Step 3 | - or - | ||

| Scotch-Brite™ 7447 | |||

| Gloss = 15 | |||

| Semi-Gloss Finish | |||

| Product | Grade | Damp/Dry | |

| Step 1 | 366L | 100μ | Dry |

| Step 2 | 268XA | A35 | Damp |

| Step 3 | 268XA | A10 | Damp |

| 268XA | A5 | Damp | |

| Step 4 | - or - | ||

| Scotch-Brite™ 7448 | |||

| Gloss = 45 | |||

| High Gloss Finish | |||

| Product | Grade | Damp/Dry | |

| Step 1 | 366L | 100μ | Dry |

| Step 2 | 268XA | A35 | Damp |

| Step 3 | 268XA | A10 | Damp |

| Step 4 | 268XA | A5 | Damp |

| Step 5 | 286Q | 9μ | Damp |

| Step 6 | Finesse-it™ Finishing Material Easy Clean-up | ||

| Gloss = 80+ | |||